1803 CRYO Series

Loading station for LNG and cryogenic fluids

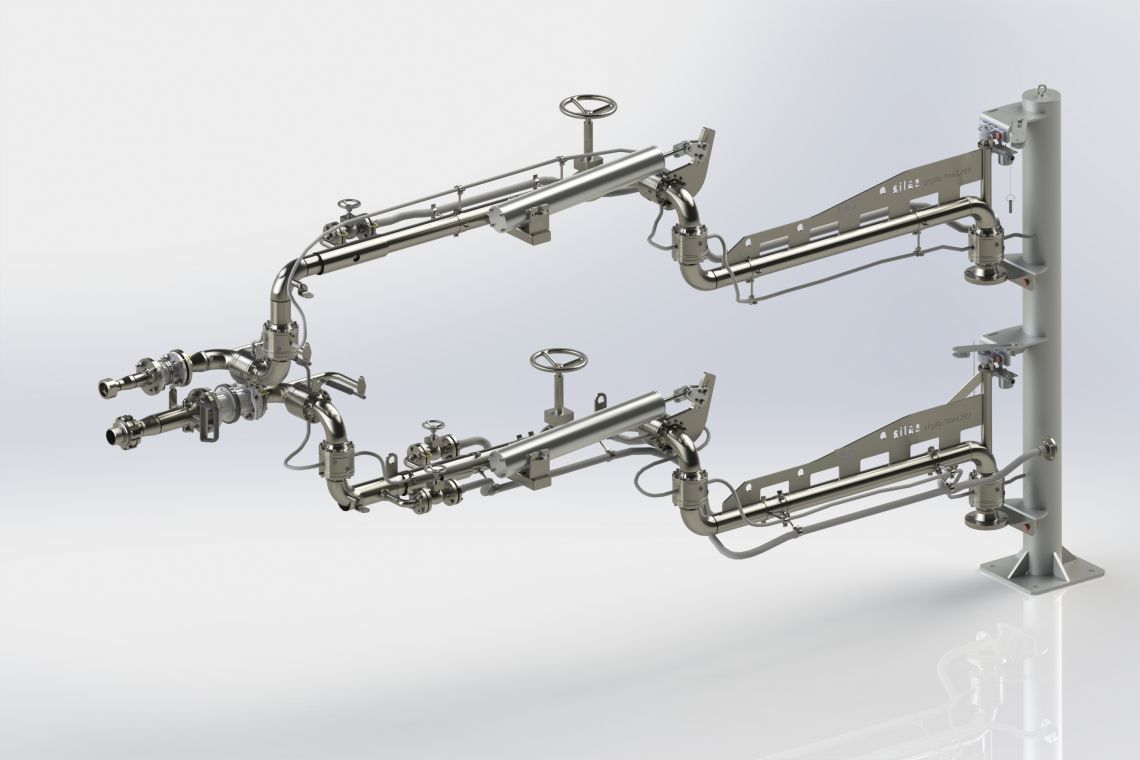

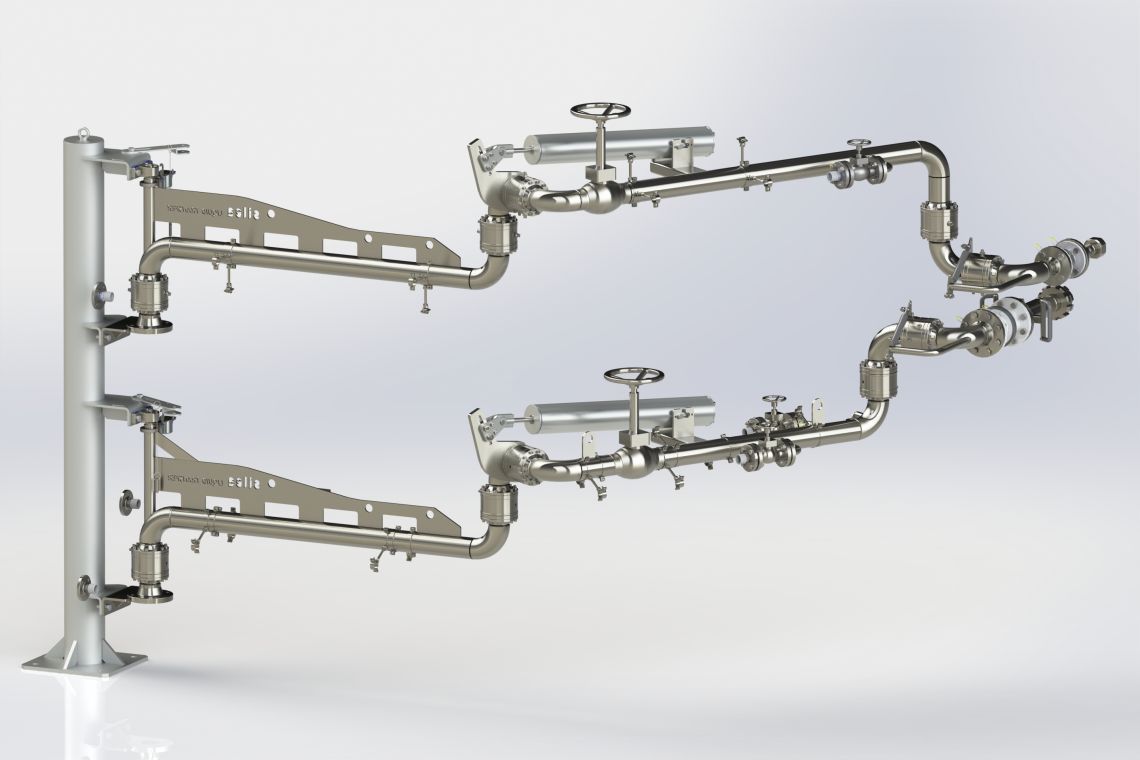

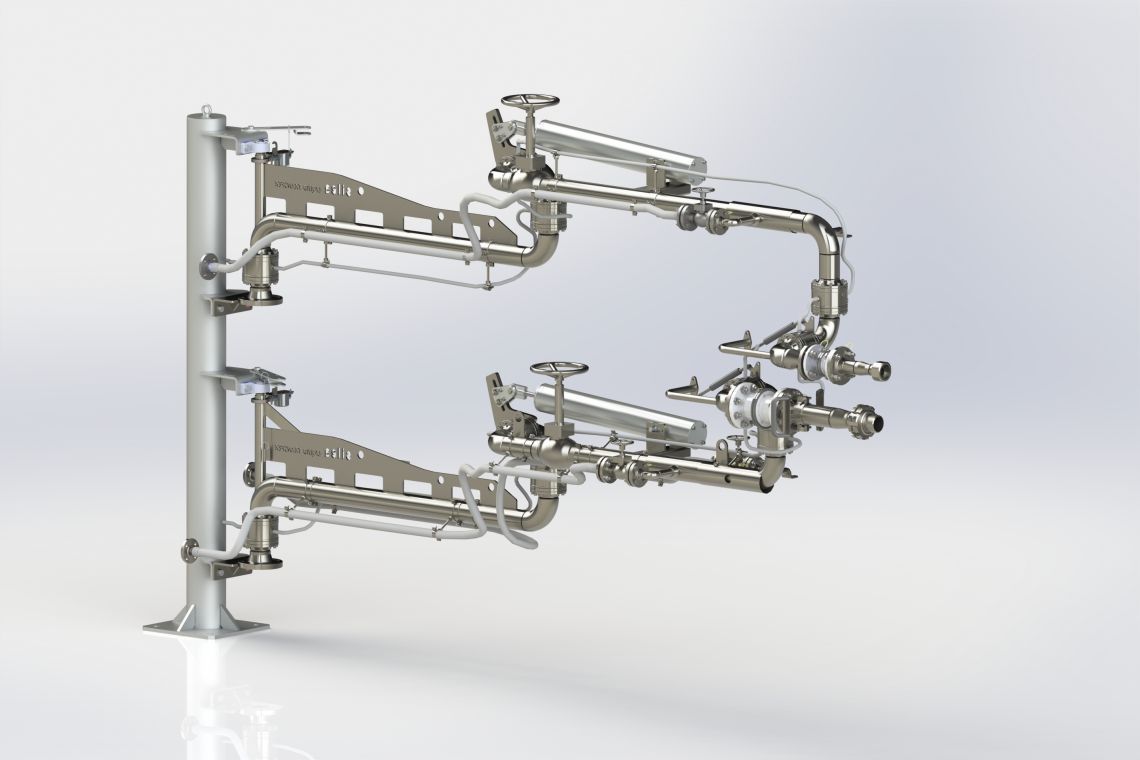

The bottom loading station 1803 CRYO series is designed for the transfer of LNG and cryogenic fluids (ex: methane, hydrogen, nitrogen...), from cryogenic plants (skids) to cryogenic tank trucks. The station is made up of two arms with a wide range of action, to allow maximum coverage of the loading area. One arm is dedicated to the liquid phase and the other to the vapor phase. The high quality materials used for the insulation of the arms guarantees the safety of the operator during the transfer activity. All station components comply with cryogenic liquid design and transfer guidelines (OCIMF and UNI EN ISO ).Request the data sheet

Get the data sheet with all the product features. Fill out the form to receive the PDF.

Features

Standard Configuration

- Bottom inlet flange ANSI 150

- Base swivel joint (C879 - F-20 style): it handles the horizontal movement. It is made in AISI316 with a double row of ball bearings and white PTFE seals specifically designed.

- Boom pipe IN AISI316: it is used to extend the range of the loading arm.

- Double swivel joint (C879 - F-50 style): It is used for horizontal and vertical handling. It is made in AISI316 with two swivel joints with a double row of ball bearings and white PTFE seals specifically designed.

- Balancing system with compressed spring piston: It is used to balance the weight of the cantilever part of the loading arm.

- Main pipe in AISI316

- ERC Emergency Release Valve PN40 flanged: in AISI316 is used to avoid leakage of liquid or vapours in case of accidental departure of the truck during loading.

- End double swivel jonts (C879 - F-50 style): this allows vertical and horizontal movement; it is equipped with a handle to facilitate the movement of the arm and two joints made in AISI316 with double row of ball bearings and white PTFE seals specifically designed.

- Globe valve: Body and plug in AISI316 with PTFE seals.

1" Drain and purge globe valve: Made in AISI316 with PTFE seals it is used to depressurize the terminal part of the arm between the main globe valve and the tank connection.

- Secondary balancing system of the end part with gas piston.

- Fitting end-connection made in brass.

- Stand-post

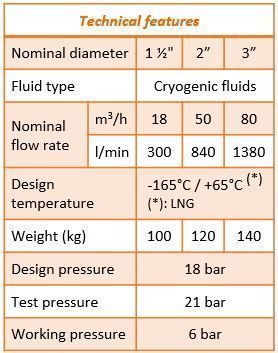

Technical features

Standard and Regulations

- Design guidelines :

OCIMF 3° Ed. 1999

OCIMF 4° Ed. 2019

UNI EN ISO 16904:2016

- Conformity Declaration of current Directive PED for Pressure Equipment

- Customs Declaration of certification for Russia, Kazakhstan, Belarus, EAC certification

- Standard ASTM-ANSI-EN

Options on request

- Top entry globe valve

- Left version

- Lateral inlet flange

- Inlet flange PN16

- Tank connection:

Messer Union (compliance with directive EIGA)

Stanag

Accessories

- Micro-switch globe valve

- Arm position Micro-switch (load or park)