02/02/2026

HOW TO CHOOSE A PUMP UNIT: A CONSULTANCY-DRIVEN APPROACH

In fuel transfer operations, system efficiency has a direct impact on operating times and process reliability. This is the case with this project carried out by Silea Liquid Transfer, which was asked to support a customer looking to improve the performance of its diesel tanker loading system.

The initial situation

The customer was using an old 3” pump unit to transfer diesel fuel from an underground storage tank to road tankers. While the system was still operational, it no longer met the customer’s operational requirements: the actual flow rate, approximately 600–700 litres/minute (36–42 m3/h), was slowing down loading operations.

The objective was clear: to increase flow rate and improve overall system efficiency, while maintaining reliability and operational continuity.

Required flow rate

The customer’s target was a flow rate of around 850 litres/minute, equivalent to 51 m3/h - a level that would significantly reduce tanker loading times and align the system with current production needs.

System context

Diesel fuel is stored in an underground tank with a capacity of approximately 50,000 litres, feeding a line dedicated exclusively to tanker loading operations. In applications of this type, flow consistency, operational stability and safety are essential requirements.

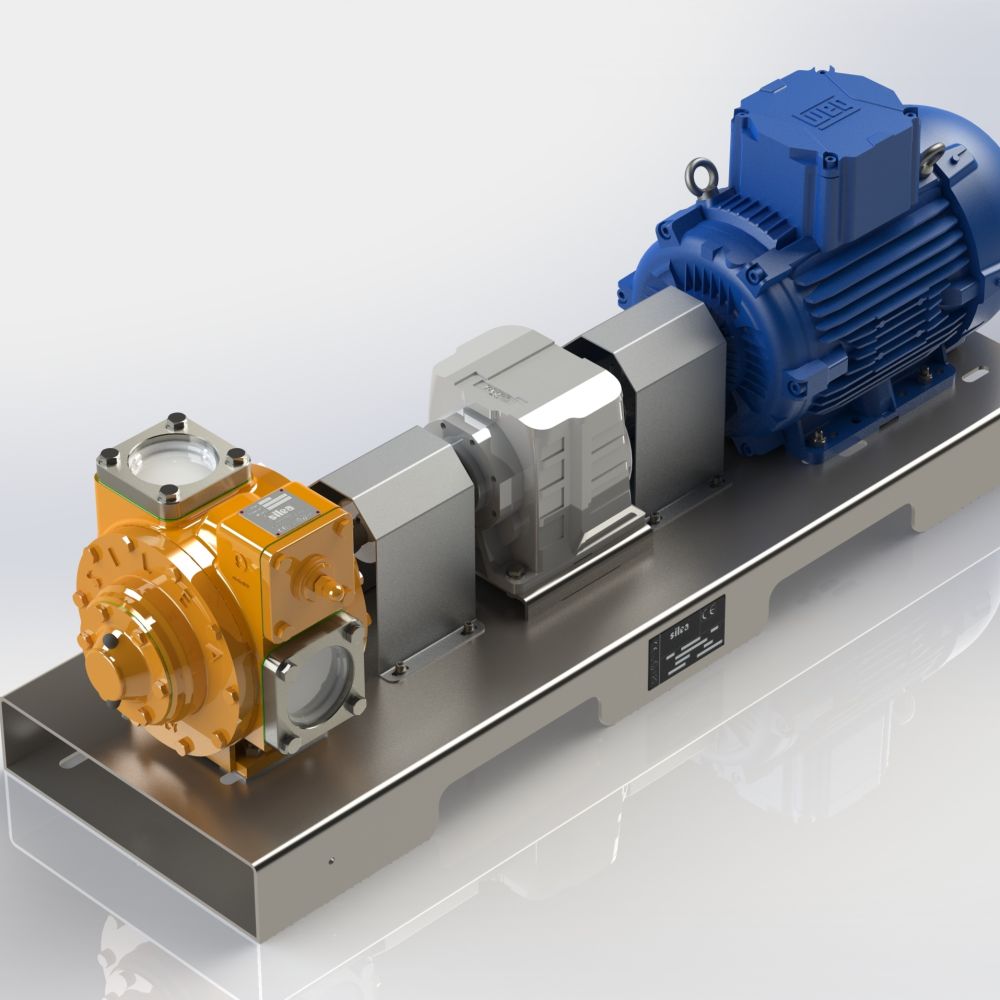

The proposed solution: a new pump unit

To achieve the required flow rate, Silea designed a solution based on a 3” pump unit equipped with:

• a 10 HP (7.5 kW) electric motor

• a mechanical gearbox, reducing the rotational speed from 1,457 rpm to approximately 580 rpm

The decision to operate at a lower rotational speed was deliberate. Reduced speed allows the pump to better match real system conditions, improving flow stability and overall transfer efficiency.

The importance of the tank and piping

During the analysis, it became clear that reduced performance was not solely due to the pump itself. A key role was also played by the suction piping - the connection between the storage tank and the pump. The existing suction line was 3”; Silea recommended upgrading it to 4”, achieving several benefits:

• reduced pressure losses

• improved pump filling

• smoother and more stable operation

• reduced risk of unwanted phenomena such as cavitation

In general, designing the suction line with a larger diameter than the pump inlet is a best practice to ensure long-term reliability and durability.

Head management and pressure regulation

From a hydraulic standpoint, the customer’s system required a head of approximately 15 metres, while the new pump unit was capable of delivering up to 35 metres. This led to a key question: how to reduce differential pressure while maintaining the desired flow rate?

The solution was simple and effective: adjustment of the bypass valve integrated into the pump. This fine-tuning allowed:

• adaptation of head to actual system requirements

• avoidance of unnecessary stress on the piping

• maintenance of the required flow rate

• no need for additional structural modifications

The tanker loading system

The system is completed by a Silea 1405 series 3” loading arm, featuring:

- manual balancing with a compression spring, for easier handling

- a Silea semi-automatic coupler, enabling fast and safe connection to the tanker and reducing loading times

Results achieved

Thanks to the overall system upgrade:

• flow rate increased from 600–700 L/min to approximately 850 L/min

• tanker loading times were significantly reduced

• system operation became smoother and more stable

• pressure was aligned with actual operational requirements

• the customer now benefits from a more efficient and reliable system

A complete optimization, not just a new pump

This project demonstrates that performance improvements do not always come from simply replacing individual components. In this case, results were achieved through a comprehensive optimization of the transfer system, involving:

- correct selection of the pump unit

- adaptation of the suction piping

- precise adjustment of operating parameters

A tailored approach that reflects how Silea Liquid Transfer addresses every application: starting from analysis of the actual system and delivering concrete, reliable, performance-oriented solutions.